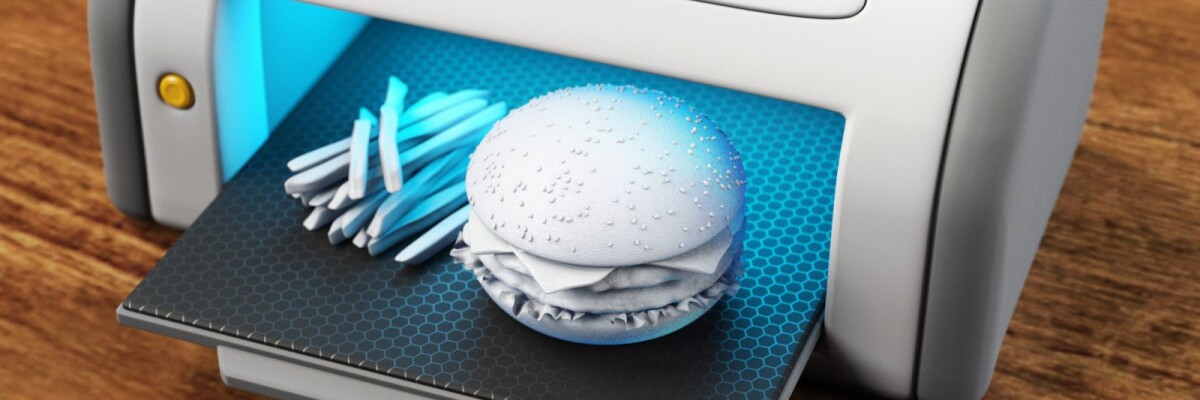

Scientists from the University of Michigan have come up with a fundamentally new 3D printing method. Instead of the traditional way of making 3D objects layer by layer using plastic fibers, the researchers...

Scientists from the University of Michigan have come up with a fundamentally new 3D printing method. Instead of the traditional way of making 3D objects layer by layer using plastic fibers, the researchers have developed the concept of the liquid base solidification using two light sources. According to the researchers, the new approach will make the printing process 100 times faster and ensure better quality of the items made. The idea was published on the university’s official website.

The key flaw of the existing printing methods is their low speed and the fragility of the objects printed: all of them have had weak spots at the boundaries where layers join together. The use of a homogeneous base solves the issue, since the objects have a monolithic structure, and the use of special additives can make them even more durable.

In order to show all the advantages of their new solution in practice, the inventors have posted a short video featuring the process of printing the letter «M».

It was also noted that all necessary patents had already been submitted to respective institutions.

Share this with your friends!

Be the first to comment

Please log in to comment