3D used to be known exclusively in cinemas. But in recent years 3D printing has become increasingly popular, and is sometimes called alternative design. The technology was first introduced in 1984. After several decades it has the possibility to change the world beyond recognition.

What is 3D printing?

3D printing is the process of creating a real object based on a three-dimensional model. The model is transferred to a special device - a 3D printer, which creates the desired object layer by layer.

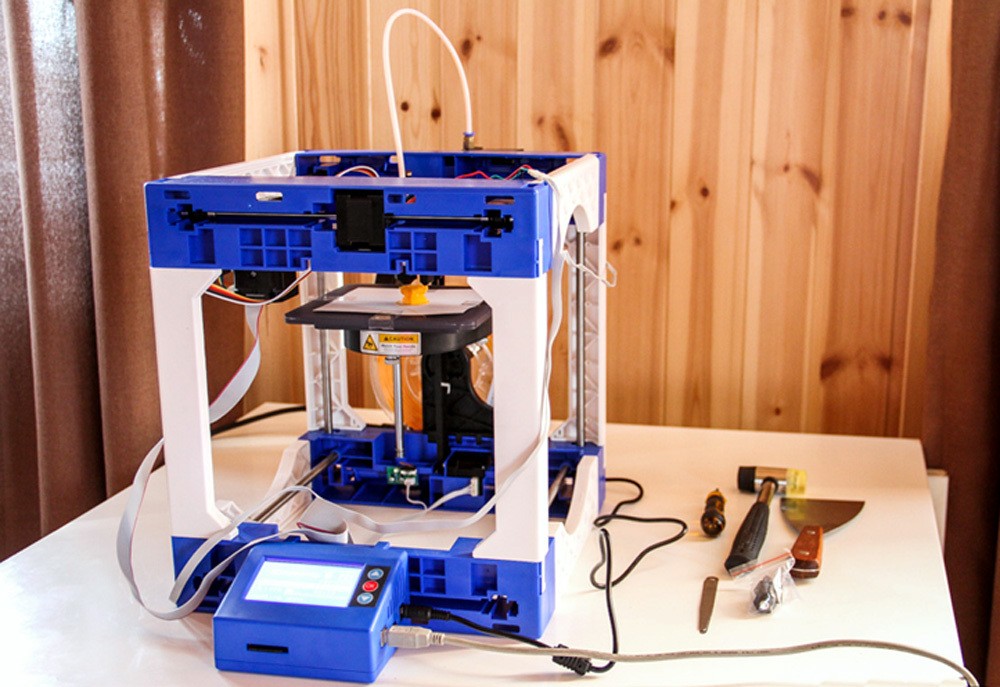

There are a great many 3D printers available today: from small indoor options which anyone can afford to buy to large industrial options with a large number of print heads. The price of such models can be thousands of dollars.

An example of a compact 3D printer:

Objects can be printed from practically any material, although plastic is the most commonly used today.

Types of 3D printing

There are several basic printing technologies.

Laser stereolithography (SLA): uses a laser on a liquid photopolymer which is converted into a solid plastic as a result.

Advantages: speed, accuracy, minimal failures.

Disadvantages: high cost, small color palette, fragility of the product.

Selective laser sintering (SLS): sprays multiple layers of a hardener onto a powder layer. The procedure is very similar to SLA, with the difference being that in the previous method the powder is distributed itself. This option is not available in SLS.

Advantages: rich color palette, low waste production.

Disadvantages: production time may be delayed.

MJM fusing method: molten plastic is applied to the printing platform with a head, hardening occurs as a result of ultraviolet flashes.

DLP fusing method: the process is almost identical to MJM printing, the only difference is that DLP uses ordinary light, which results in a slower production speed.

Polymer Overlay (FDM): FDM printing resembles the work of inkjet printers. The gradual melting of a plastic rod leads to the formation of small droplets that are applied to a moving platform in the correct place.

Advantages: the richest color range, simplicity of technology, availability of consumables, durability of products.

3D printing application

Cooking

It sounds unbelievable, but there already 3D printers today that are being used in such areas as cooking. They can be especially useful in the preparation of unusual "architectural" dishes, such as wedding cakes (and not only).

Here is a short video that tells about the world's first printer that can “print” chocolate products:

Building

Another practical application of 3D printing technology is construction. Housing will soon be more beautiful than ever and affordable. With new technologies it will be possible to build them in a matter of hours and the cost will be much lower than today.

A house fully printed using a 3D printer in Russia:

And here is a similar house in Milan:

By the way, the U.S. Department of Defense is interested in the technology and is even considering the possibility of printing soldiers' barracks.

It would take 10 people about 5 days to create a similar wooden construction, while the 3D printer completed it in 40 hours.

Production

3D printing marks a completely new era in production... of anything! From toys to bicycles and from jewelry to rockets.

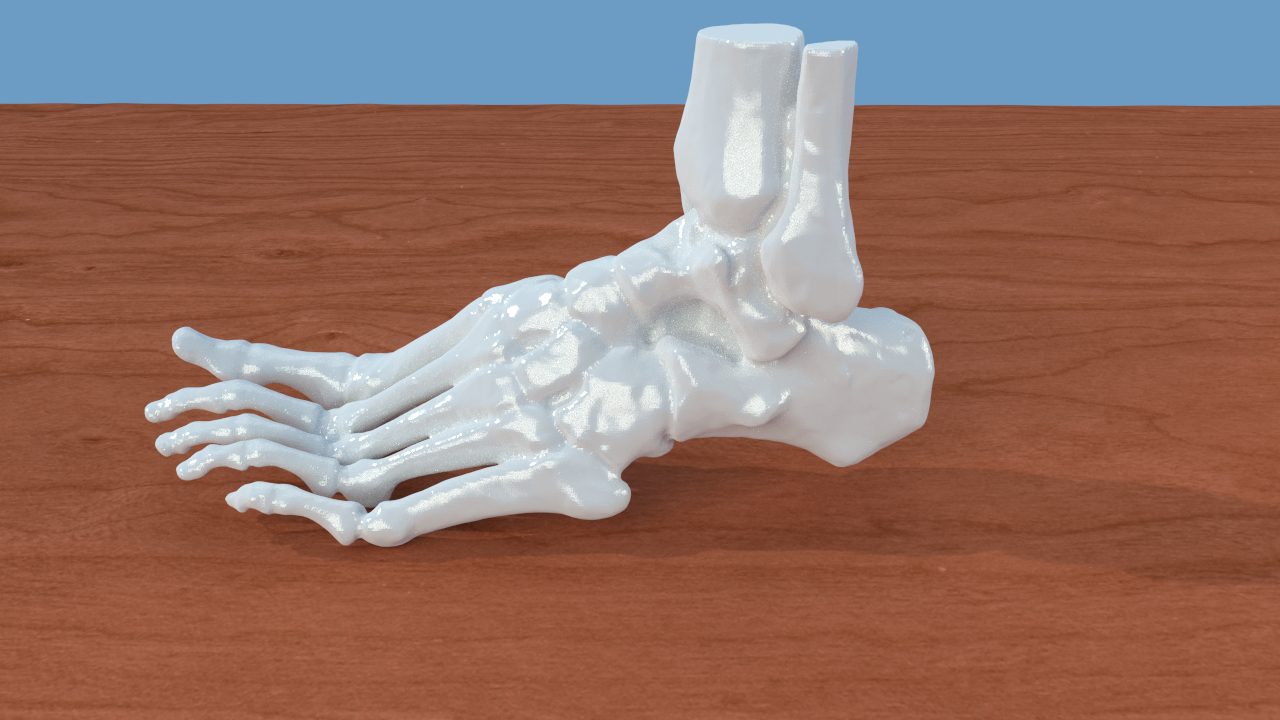

A perfect example is this life-size model of the human foot:

And in the near future scientists will not only be able to create artificial limbs, but also to print artificial organs from scratch, because they have already learned how to use living matter as a material. We are talking about researchers from Zurich, Switzerland who have developed unique biological inks, excellently suited for creating biochemical structures.

Problems

The problems associated with 3D printing are becoming more apparent. The fact is that many people are trying to do illegal things with this technology. In particular, we are talking about firearms. Since it is impossible to identify a “printed” firearm, members of the public are beginning to sound the alarm.

A metal gun printed on a 3D printer:

In some countries in the world, laws have already been adopted that not only prohibit “printing” weapons, but also distributing instructions on how to do it. Moreover, some experts say that it is necessary to introduce methods for identifying printers, so that you can tell who made it by looking at a part.

Share this with your friends!

Be the first to comment

Please log in to comment