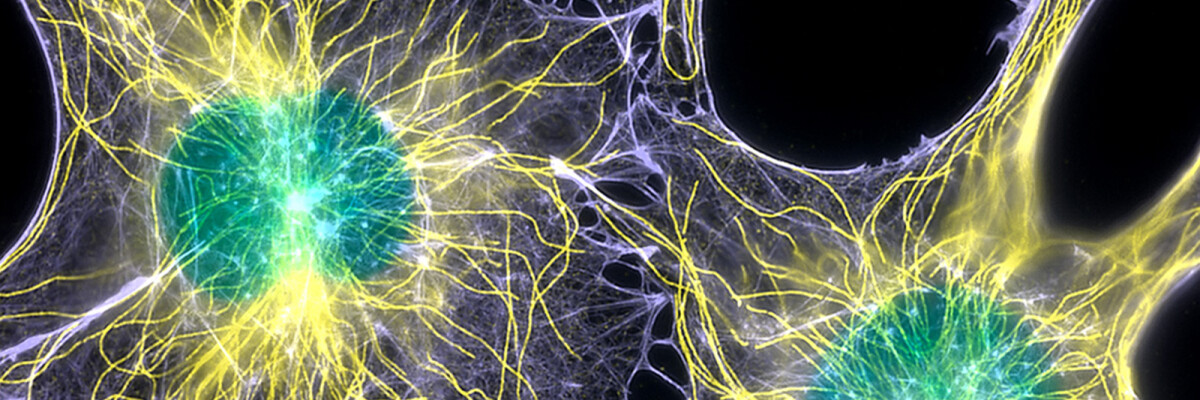

The new method is not only faster than layer-by-layer bioprinting, but also enables more complex structures to be created with minimal damage to cells

The Federal Polytechnic School of Lausanne (Switzerland) and Utrecht University (Netherlands) have presented a jointly developed technology enabling almost instant printing of complex three-dimensional biological tissues. Using the new method, the scientists have already printed out several complex three-dimensional tissues, such as a heart valve fragment, crescentic cartilage and part of thighbone.

The method is based on the following principle: stem cells are placed in a special rotating tube filled with hydrogel. A focused laser beam directs energy to specific points where tissue needs to harden. Once the basic shape is created, endothelial cells are added to the tissue to create a network of blood vessels for steady delivery of nutrients and oxygen to all the cells.

So far the technology can be used to obtain sections of biological tissues up to several centimetres in diameter. Among the advantages of the method, as highlighted by its authors, are high process speed (just a few seconds) and the capability to create shapes of any complexity. Moreover, the printing process is so low-impact that almost no damage is done to stem cells making them higher quality samples compared to the existing ones.

The developers expect that it will now be much easier to produce complex tissues. The first practical application of the technology will be the printing of samples to test new drugs. In the future, once the entire process has been improved and thoroughly tested, scientists hope to be able to grow organs for implantation with patient-specific characteristics.

Share this with your friends!

Be the first to comment

Please log in to comment